A Matter of Cost

A few months back we were beginning to get into a situation where we needed more studio lighting. However, our studio is much smaller than what we had available in our previous house, so we really didn't have the floor space to continue positioning more gear around the room.

I starting researching options online and eventually came across some really amazing rail systems on various websites. However, they were quite expensive. Some where several thousand dollars and still required a lot of assembly. This got me thinking about if it would be possible to simply build it myself from parts that I could purchase locally from Home Depot or Lowes.

Choosing the Lights

When I first decided to take on this project, I was humming and hawing about what kind of lights I wanted to get. Being that it was already getting a bit cramped in the studio, I wanted to find some soft lighting that emitted a lot of lumens yet in a low profile form factor. After reading a lot and watching quite a view review videos on YouTube, I ended up settling on pancake, or flapjack lights.

As the name implies, these lights are round and flat. But don't let that fool you - these lights are way more powerful than you might expect! They are a massive upgrade to my previous LEDs and are generations ahead of my old, extremely hot traditional lighting. And through quite ingenious design, these units emit beautifully diffuse light without the need for a softbox. This dramatically reduces the space requirements.

The actual lights that I purchased are Neweer brand. I believe these are a knock off of the Fotodiox pancake lights, but from everything that I can find online; they seem to be virtually identical- except for having a much lower price tag. They are still available for purchase on Amazon here in the US.

The Rail System

This part worked out surprisingly well once I acquired the right components and got my head around exactly how I was going to mount everything. I knew that I wanted to use some kind of rolling system. I came across a video on YouTube of a guy who used channel struts and wheels to hang and roll objects across the ceiling. This seemed like a perfect system for my needs.

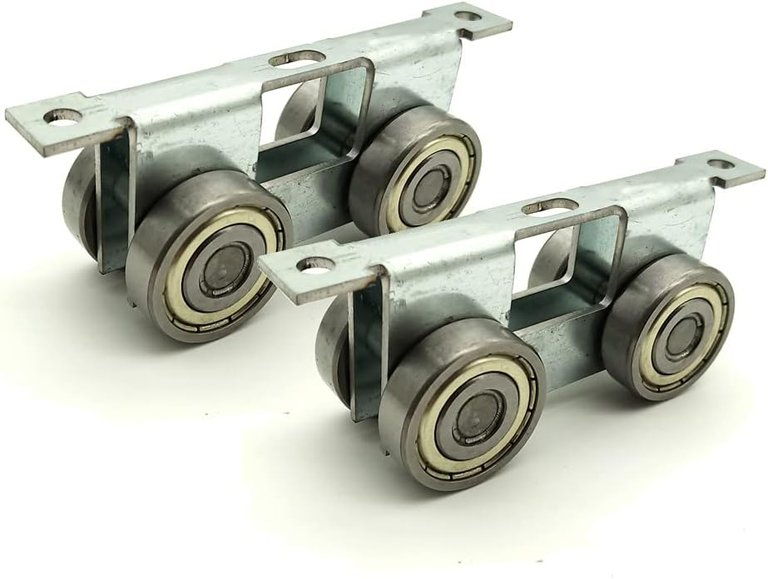

I knew that I was going to be using 4 wheel roller trolleys which require 1 5/8" slotted Unistrut. I ordered the Trolleys online here but I still needed to get the struts themselves. I didn't want to get them online because I was pretty sure that the weight would make the price quite prohibitive. I had never purchased Unistrut before, but I did recall seeing them at Home Depot.

After a trip to several Home Depots around town I was unable to find the 1 5/8" variety, so I took a trip across town to Lowes where I finally found the motherload! I wish that I had just looked there to start with after not finding them at the first Home Depot. I kept looking there because they actually did have a space for them on the shelf; they were just out of stock everywhere for whatever reason.

So now, armed with the struts and the trolleys, I went ahead and grabbed some 3/4" pipes to and ran them across, between the two struts. If you look at the animated gif at the bottom of this post, you can see how the dual pipes are attached to the trolleys. Basically, they are evenly spaced using a piece of wood and held together by two clamps on either side.

The last important part that I needed was the channel strut hangers that would allow the trolley to pass through unimpeded. They needed to be rated to hold a decent amount of weight so I paid a bit extra for them. I picked up a 6 pack for about $40 on Amazon here.

Mounting the Boom Arms

When deciding how to mount the boom arms to the rails, I initially thought to use some kind of fancy trolley system similar to the struts, but in the end I decided against it because I actually wanted a bit of friction when sliding the lights back and forth. Even though it would make it a lot easier to move the lights if they were on wheels, this would also have the side effect of allowing the boom arms to roll around on their own at the slightest movement. This is not ideal once you have you setup fine tuned. I also bought the boom arms on Amazon here.

As you can see in the above image, I used 3/4" PVC pipe straps to hang the boom arm assembly. These allow the arm to slide, but with enough friction that it won't move around on it's own. Time will tell if this was a good decision - but so far it has worked out great! We have already done several projects with them and it has really made it a lot less stressful on set not having everything on the floor.

My Final Thoughts on the Project

It is hard for me to make an argument that this was not worth the money I saved doing it on my own. There was certainly a bit of trial and error, but it really wasn't that difficult. In total, I believe the whole thing ended up costing me about 200 USD to complete. Don't hold me to that though, I can't remember the exact number! But when you compare that to $2000-4000, it is a no brainer. I am sure that the systems you can order are a bit slicker, but in my opinion it can't make up for the wildly massive price difference.

I would really appreciate your support!