Well Hello There Fellow Technicians And Hivers

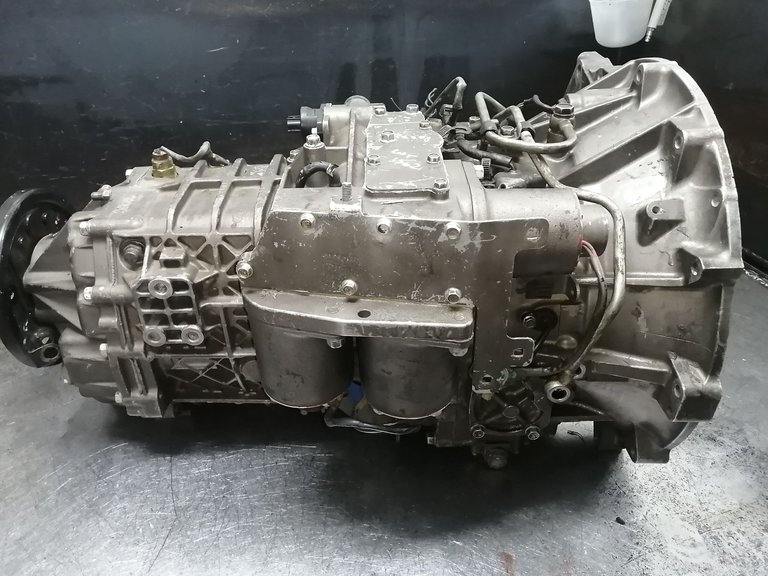

See this? Yeah we're busy with the big trucks again, I've mentioned this a few times before where I say that the jobs comes in pairs. This is what I mean... we've been getting a bunch of truck transmission and differentials to fix lately, I wonder what's next in line.

Okay okay even though the work is a bit harder and heavier I do have to say I am quite excited about these jobs, I'm keen on seeing some new things and working on them aswell!

What we have here is the differential of a Mercedes V8 Actross Truck. Quite a beastly things and I do believe that it does look smaller in the photo than it actually is. Well that or I'm a shitty photographer.

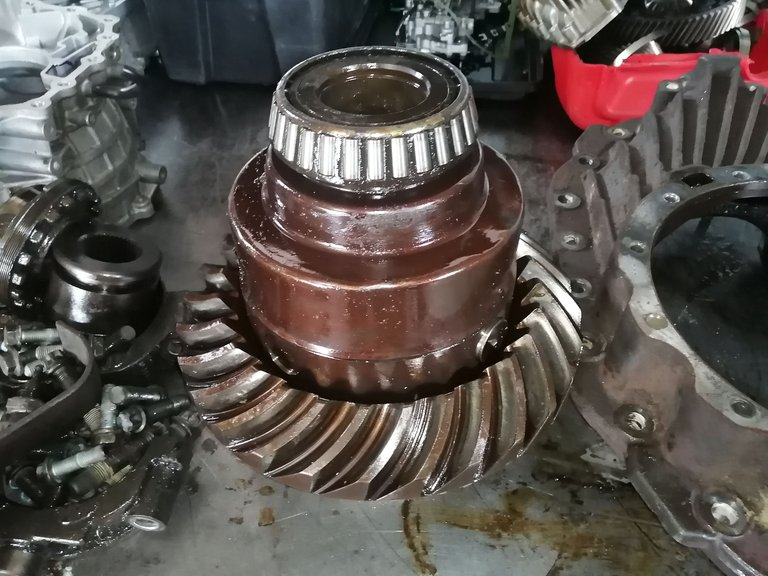

Just take a look at a few of these parts, this one in the photo below is the crown-wheel assembly and it has some thick teeth on them! Worn out yeah it will have to be replaced but it be a proper one! I do have to mention the fact that this truck has two differentials!

They are not easy to remove or put back for that matter!

Everything is massively oversize in this differential, well it's the right size for this specific model ofcourse but damn it feels like a powerful feeling holding these solid parts!

This ring I am holding is one of the bearing racers! Insane isn't it?

Yeah I tried washing my hands so that they look a little better in the photos but laughs the moment I touch the parts is grimey and greasy from the top! Remember these differentials run with 85w140 now that is some real thick oil!

I've had it before where the bolts simply doesn't want to come loose even when using airtools! As I mentioned earlier it's been quite some time, I think more than a year since we last worked on such big trucks! And well back then I didn't really know what the hell I was doing. I just went with the flow.🤣

Well we always have a plan for bolts that don't want to budge, heat... heat is always the answer. Everything moves when heat is applied that I promise you! However I don't quite fully understand that concept just yet, they say that the bolt expands therefore it comes loose, but in my head if the bolt is expanding isn't it suppose to press even harder on the threads?

I don't know, perhaps I'm bat shit crazy!

Needless to say the heat worked perfectly, I heated up two bolt heads and shot them loose with the airtool!

So I got the bolts removed which holds the crown wheel to the whole assembly, but I'll be waiting for the morrow so that someone can help me to fit this one into the press, that crown wheel is fitted on there as tight as can be.

Rather safe than sorry I suppose!

After all that thing weighs half of what I am currently weighing! That's majorly heavy for such a piece of metal, well I mean it is a solid chunk of metal!

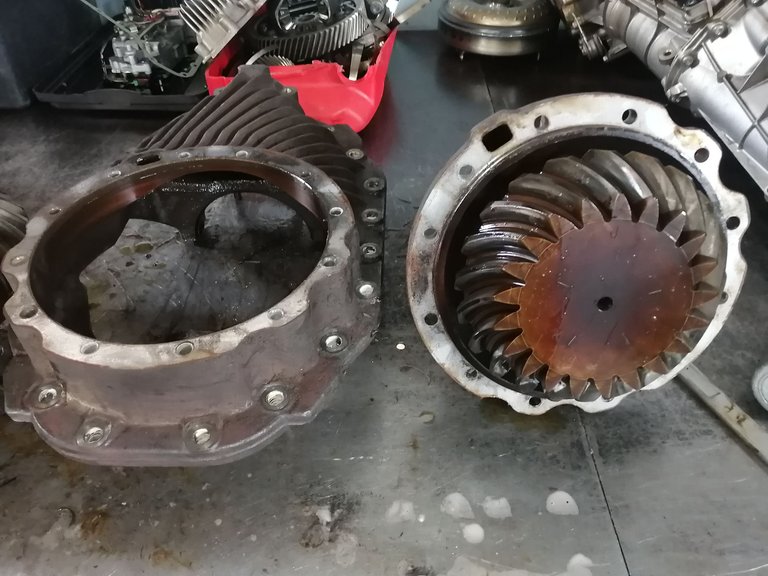

I almost forgot, it's not the only big piece of metal in that differential. A differential consists of a crown wheel assembly aswell as a pinion that drives the propshaft, along with the bearings, casings and seals of-course. But mostly its the crown wheel and pinion shaft.

The pinion shaft of this one bolts on to the casing usually they press into the casing itself but this one is so huge that they had to forge it's own separate casing for it.🤣

Well these are waiting for the morrow to finish the stripping on them, luckily we have already assessed the damage and can order the needed parts! So this won't be a delay at all!

I'm not done with the big drive trains yet! Stay tuned for this one next up!

Connecting the people of #HIVE across South Africa. #hive