I’ve been in the Lineman trade for 18 years. 3-1/2 year apprenticeship working God only knows how many hours. For 10 years me and boys built or rebuilt hundreds of miles of powerlines in California. It could be thousands who knows. When one job consists of 30 miles worth or re-conductoring it adds up fast. 30 miles time 3 wires… that’s 90 miles of wire right there. It’s kinda crazy when I step back and think about it.

Driving by a powerline rebuild is one thing, just poles, transformers, switches, and wire… blah blah blah Same ole stuff basically. Now working and living in Washington state, the type of work is a little different to say the least. Given the opportunity to build a substation from the ground up… I’m in!!. Building a substation was something I had never done. 8 years later and it still standing and in one piece… we must have done something right??

There is a lot to building a substation even before the ground gets broke for the concrete foundations. You know a whole bunch of that engineering stuff that looks good on paper but half of it actually works out in the real world. wink:wink All that stuff happens then we get plopped with the prints and are told to build this… “Sure… OK…”

Before we can build anything above ground there is a ton of work that needs to be done below the dirt and rocks. All the conduit for all the control wires and the Ground grid. 2 feet under the ground and layer of rock is a ground grid. It consists of 4/0 copper laid 2 feet deep forming 8ft by 8ft squares over the whole fenced in substation yard. Then about a million 12 foot ground rods are driven into the ground. 2 of us spent 3 days just installing ground rods. We even had an electric ground rod driver. The copper was cad welder together at all crossings, ground rods, and every other fence post. To think, this is all stuff you don’t even see and it took us weeks to finish. All that work just to cover it up with dirt and rocks…

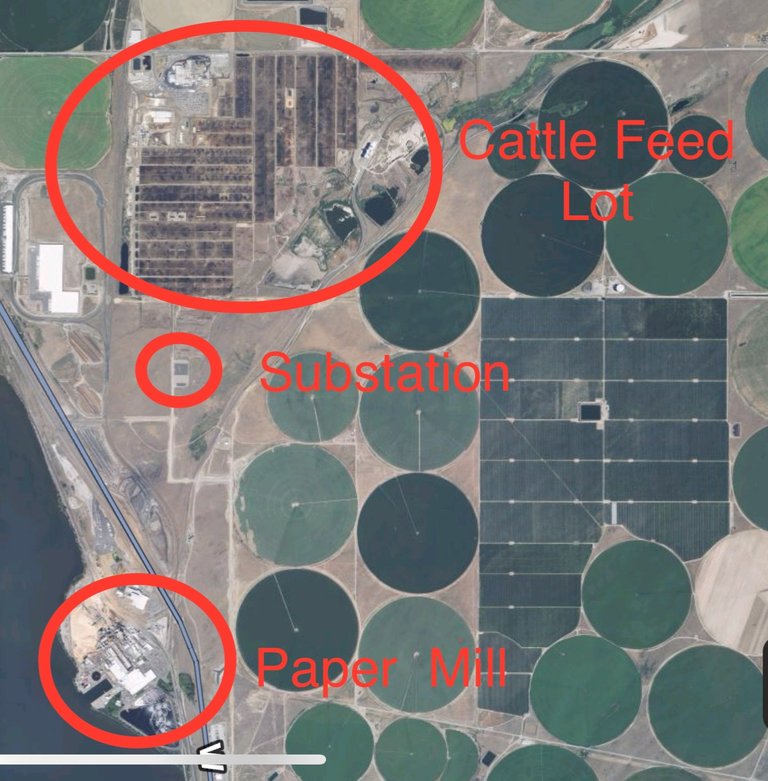

This substation was built just off the Columbia River between a cattle feed lot and a paper mill. The paper mill itself put off a very… distinct stench. Almost a rotten wood, mildew, puke stench. So ya, it’s not the most pleasant of smells. Then you get the sweet aroma of the cattle feed lot mixed with their processing of fertilizer which they did just outside the fence 100 yards. Blend those together on a 110F day… hmmm… that’s real nice… 🤮

The nightmares are coming back… the flies… the flies were absolutely horrible!! Simply open the door of your truck to get out… 10,000 flies are in the cab. Dang shit eaters!! We would spend the 45 minute drive back to the shop swatting flies with out hats.

<center“Roll the window down” one might say”

These little a-holes would hide behind the seats or wherever they could. Roll the windows up… they are still there. Fly guts were smashed all over the interior of the windows by the time we got back. It was a daily battle of Man vs Fly.

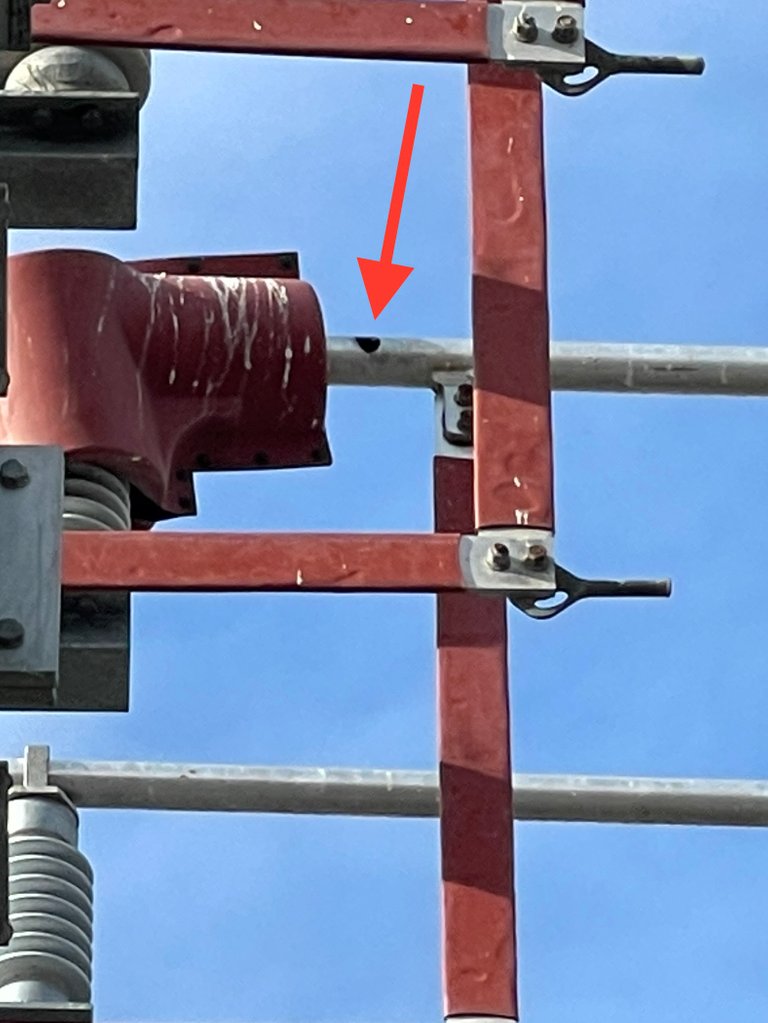

This substation being next to the Columbia River was a great place for the many birds inhabiting the area to perch, nest, and poop… lots of poop. Excessive amounts of poo can be pretty conductive. Just a little FYI… 2 of us spent 2 weeks installing Bird Guard over the energized wires and buss tubing. Day in and day out… cutting, heat shrinking, cutting heat shrinking… You wouldn’t think so but this Bird Guard stuff is expensive!! I’m talking 10’s of thousands of dollars kind of expensive. All that just for the birds… yet we still had those little birds nesting inside some of the insulator covers. We thought we had this substation all covered up and there was no way a bird would be able to commit suicide and cause an outage. Boy were we wrong. A few years after construction we ended up shutting down the whole substation and installing even more Bird Guard.

Recently we had to shut the substation down to repair a whole in the main buss work. A big Raven managed to contact the energized tubing and the grounded structure. This caused the the main circuit breaker to open. The electrical fault was that intense.

Having never built a substation before I was blown away at how much work was involved in doing so. All the wiring was measured, cut, and bent the same, so that each circuit looked as identical as possible. Sometimes just trimming off 1/2 inch of the wire made the difference. All us Lineman working on this substation had the same sense of craftsmanship and pride when building this substation. Our goal was to make it the best looking substation in the system. Pride in our craft.

Remember when I mentioned about how things work on paper but not in real life… Ya, the construction of this substation didn’t go without any setbacks or changes. Lots and lots of changes. A ton of them were small changes that we could make on the go. Then we had steel beams that were built 2 feet short, except they were the exact measurement per the prints. The opposite side fit fine, concrete footers were spaced correctly… but I guess the 2 foot difference was overlooked. Welded on brackets in the wrong places, yet they matched the print… those are just a couple things I remember that were big issues. I’m just glad we didn’t have to do the control house wiring… those dudes had a nightmare on their hands. Lol

As Lineman we don’t spend that much time in the me place. The scenery is constantly changing and that’s what I live about it. Except when building a substation…

I do monthly substation inspections at this substation. Honestly I look at it and say,

I don’t care what craft you are in, if you don’t look back at your hard work and admire it… you did it wrong.

Your Random

Dose of...