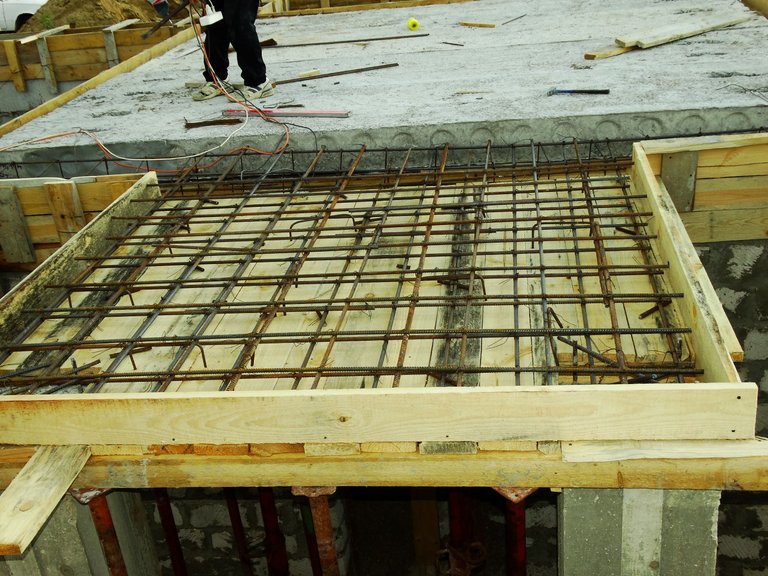

Reinforcement of the floor slab and reinforcement of the formwork.

Greetings, friends!

It's time to continue the construction of my two-story house, which I talk about in the wonderful Architecture + Design community.

Such an exchange of experience is very useful, because you can see with your own eyes each stage of construction work and will weigh your forces before starting your own construction.

I love to get information from great authors, architects, builders, designers and anyone for whom architecture is a hobby.

This allows me to evaluate my own actions, perhaps to revise some nuances in the further conduct of construction work and to consider new ideas for the design of finishing the house, after the completion of construction.

It is very important to know that there are people who can be asked a question about construction and get a meaningful and complete answer to it.

In a store, you cannot buy it, there, life experience is not for sale! lol.

So, I will continue my story.

As you remember, if you read the previous articles, we prepared the formwork for pouring a monolithic belt, which, like a vice, should compress all levels of the foundation of my house.

But, it was decided to postpone the order of concrete for a while and to mount a floor slab over the vestibule of the basement and, additionally, to strengthen the formwork around the perimeter of the entire house with stiffening ribs.

Reinforcement of the floor slab.

When I, with an engineer, discussed the project of my house, I made a bet that all floor slabs will be of standard sizes, which are produced at factories in Moldova.

These floor slabs are hollow, which means they are light, and they were created taking into account the seismic activity of the region. The norms by which such plates are made were established back in the USSR, when they did not save on materials.

But, I have not provided for one floor slab.

The staircase of my house passed in one light from the basement to the second floor, so it was, according to the project.

I decided to separate the underground part of the house from its aboveground part and the designer, at my request, made changes to the project and calculated the reinforcement of this slab.

As you can see in the photo below, this is not a very simple structure, which required certain metalworking skills to create.

This solution allowed me to combine, into a single whole, this floor slab, typical floor slabs above the basement room and a reinforced belt along the perimeter of the house.

It should be noted that these were unforeseen expenses that were not included in my estimate, but, sometimes, you have to make tough decisions.

As you can imagine, there was an unforeseen consumption of everything, boards, screws and dowels, concrete, fittings and working hours.

It seemed to me that this job would take at least a week. But, everything was ready in two days.

Let's move on to the next type of work that had to be done before ordering the delivery of concrete.

Reinforcement of the formwork.

I was worried that the mass of concrete that would pour into the formwork could break it and I decided to strengthen each section of the formwork.

Now, it's hard for me to say how much a 50x50 mm wooden beam was required, but it would be possible to rebuild a nice arbor from it, that's for sure.

But, I had to cut it and stuff it every meter and more often, onto the longitudinal parts of the formwork.

Perhaps you will say that there is an overrun of the timber, but, as they say, walking like that, lol.

Many construction projects in this region are conducted without direct access to electricity and water, they have to use generators and bring water in barrels, I thanked God a hundred times for the decision to carry out all communications before the start of construction work.

In this photo you can see the water tower, which is the source of artesian water for my house.

Many villagers complain that they do not have enough water pressure, but, fortunately, I am the first subscriber and the water pressure is always strong.

I said that the knitting wire with which the boards are sewn is a waste of materials, but this is additional reinforcement of the reinforced concrete belt.

You can see a car that delivered telescopic racks and many bags of cement to the construction site. Probably, the French could not imagine that this is possible, lol.

It was a wonderful, sunny day, white clouds were floating across the sky, but I saw it only by looking at the photographs, I was too busy with calculations, to notice this beauty.

Продолжение следует!

Enjoy your viewing and reading!

Blessed day to you!

| Category: | Architecture + Design |

| Camera: | Sony Cyber-shot DSC-HX300 |

| Location: | Moldova |

| Author: | @barski Ukraine For my publications, I am not a vikorist stock photography, for me it is fundamentally important to vikoristovuvat for the publication of photography, as I shattered with my hands, and I can name them - author's robots. |