Heeeyho Readers! Let's talk about some minor issues.

Dealing with a 30-year-old mountain-bike is not smooth sailing. Matching newer parts to older frames require some thinking at times. The biggest challenge in this monster cross project is combining a 90's frame to early 00's brakes and modern drive-train. Some minor bits don't quite fit and need re-designing — the case with the v-brake mounting pivots.

The original brake pivots on my frame look rusty, so I decided to buy a new pair. My perfectionism kicked-in real hard, resulting in a longer-than-desired research. Well... After a long time online I came across these beautiful titanium pivots. Bought a pair.

The titanium pivots are incredibly well built, weight nothing, and will never rust. Not gonna lie... it tastes bad to have such fine bolts hidden from view — because, yeah, nobody is gonna ever see them once the brakes are installed. However, as the saying goes "perfection is in the details".

The new pivots matched the threads on the frame (8mm), but I soon discovered that these old bikes used to use cantilever brakes, which, in turn, use slightly different pivots (the ones I have). There are essentially two different pivots. My v-brakes happen to be for the second type, that have a shallower mounting base. The higher base on the pivots I have won't let the brake arms go all the way in.

Problem equals solution

Everything is possible from the engineering standpoint. Might require some re-designing and unwanted machining time, but it is possible! Isn't problem-solving the beauty of these weird projects?

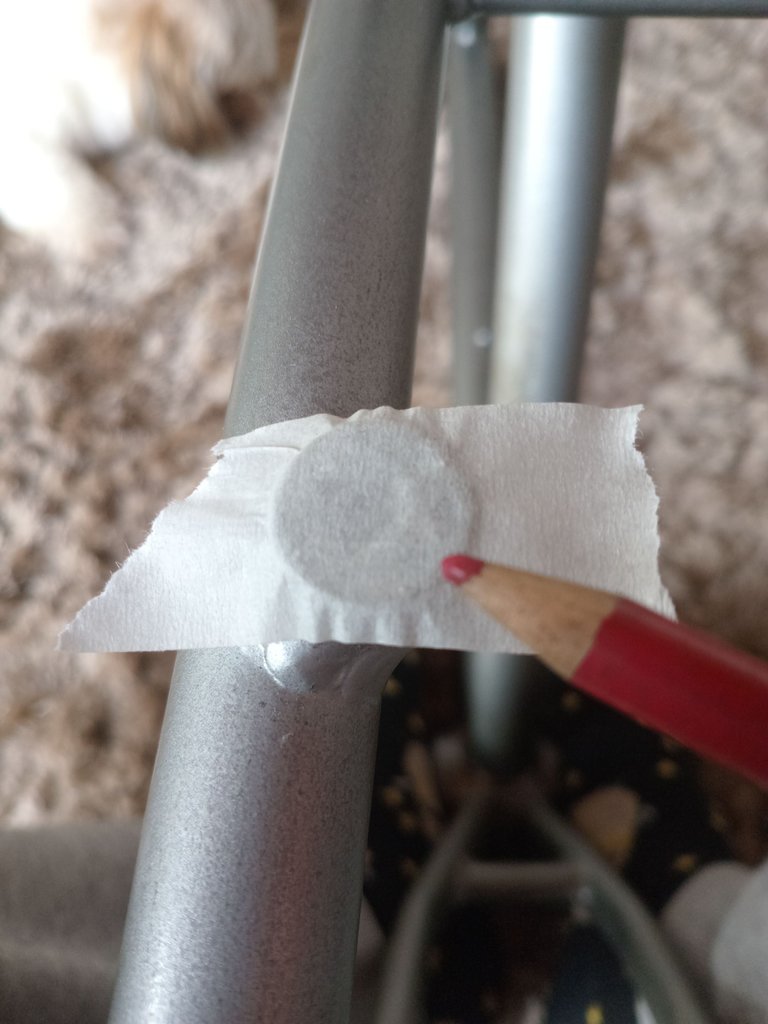

As you can see above, the v-brake arm doesn't go all the way in. It should attach flush to the frame, and that small pin goes into one of the three holes on the frame, which tensions the spring.

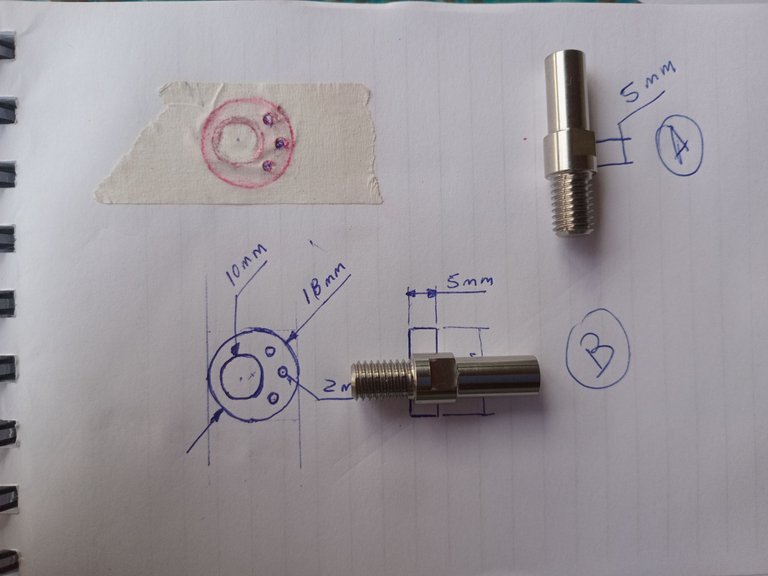

One obvious solution is to re-machine the pivot on a lathe to make the base shallower. That's the easy way, although I don't like the idea of modifying those beautiful pieces. Designing an aluminum base to go between the arm and the frame isn't difficult and should solve the 5mm difference.

Edit: Pivots with a shallower base exist, but those have 10mm theads that won't screw into my frame (8mm).

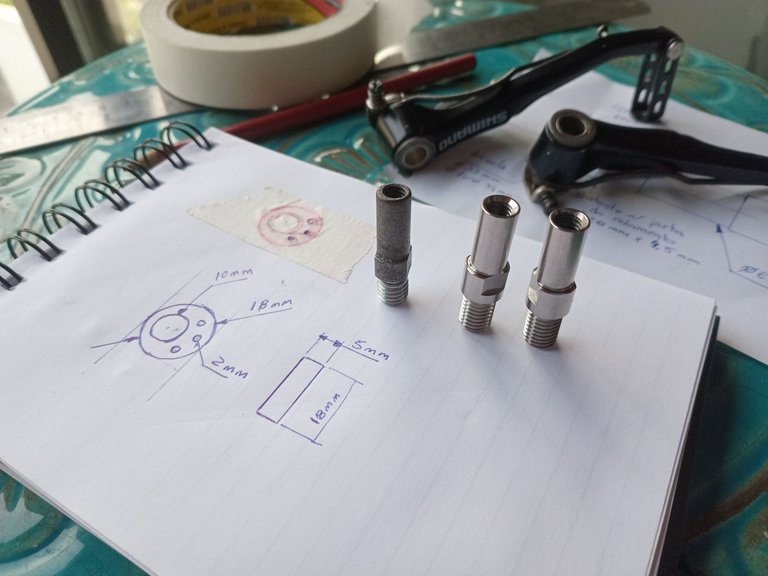

I used an old trick to transfer the dimensions from the frame to the "drawing board". The adapter will have the same dimensions by 5mm of thickness, equivalent to the gap between the arm and the frame.

The concept sounds fancier than the actual execution. Think of it like a new base for the brake arm, as shown below. An easier solution is shown on A (taking 5mm out of the pivot, which involves machining a beautifully made titanium piece).

B is the second solution: an adapter that will attach to the frame. The pivot goes through the adapter, hence, taking the 5mm difference. With the adapter, the little pin (spring pin) will be able to function.

Is it extra work? Yeah, it is. It's either that or choosing a different braking system. I guess the fun lays in designing such solutions. In the end, the adapter will look like part of the frame.

Finding solutions to mechanical problems is what drives me. I guess there's nothing as satisfying as fitting parts we designed and thought about. The last step is to pay a visit to my local machinist and report back to the readers. {fear}

Will it work? Place your bets ladies and gentleman.

Peace.

If you enjoyed this post consider leaving your upvote for a hot coffee.

Find me on Twitter: https://twitter.com/mrprofessor_

~Love ya all,

Disclaimer: The author of this post is a convict broke backpacker, who has travelled more than 10.000 km hitchhiking and more than 5.000 km cycling. Following him may cause severe problems of wanderlust and inquietud. You've been warned.