Working with my hands is something I enjoy whether making something creative, doing handyman stuff and DIY, holding donuts and coffee, gardening or performing a random task of some sort; I get satisfaction out of standing back at the end and saying, I did that.

As a shooter who makes his own ammunition, my hands are often busy doing that and over the last couple weeks I've been making a lot of ammunition for all of the calibres of firearms I own.

Yesterday, I was focused on .243 rounds. I've been doing the preparation work on the cases over time, some of which I've written about before here, and recently worked on the last stage, adding the gun powder and projectile to finish off the ammunition completely.

This is a fairly slow process for me as I don't use any automated or electronic equipment. I figure it's best to know how to do it without and I find I'm more precise when doing it myself, with my hands and brain.

When shooting at long range I'm looking for precision, accuracy and repeatability which starts with the ammunition. Making it myself, to my exacting standards, means I can be very precise and a low standard deviation (SD) in muzzle velocity means better precision, accuracy and repeatability down range. Mass-produced factory ammunition can never be that precise as they need to push out millions of rounds very quickly. About ten billion rounds are made in a single year in America alone so they're not as precise as handloads.

Anyway, because this stage isn't messy and happens quite sedately I took a few photos as I went.

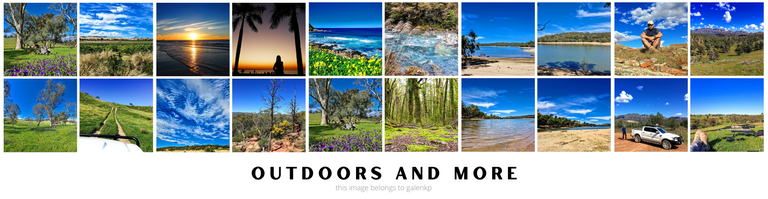

Below is the powder I use for this particular ammunition. It is ADI AR2209 made here in Australia. I've developed a load specifically for the rifle this is used in which consists of 40.9 grains of powder. That doesn't mean 40.9 individual little pellets, a grain is a measurement of weight. For perspective, 437.5 grain-weight is equal to an ounce so you can see, it's a very small measurement.

Above you can see a single AR2209 gun powder pellet on the tip of my finger and another sitting on the tip of a set of standard tweezers. I use the tweezers to add or take a pellet here or there to make sure the 40.9 grains is measured precisely. This is why it takes so long.

Also above, you can see many grains in the hopper (dispenser) that I use to throw the 40.9 grain-weight - I set this to the precise weight before the process begins but (of course) it's never perfectly accurate hence the tweezers. Below is a partial image of the hopper. It has a little handle I work up and down to release the set-measurement of powder.

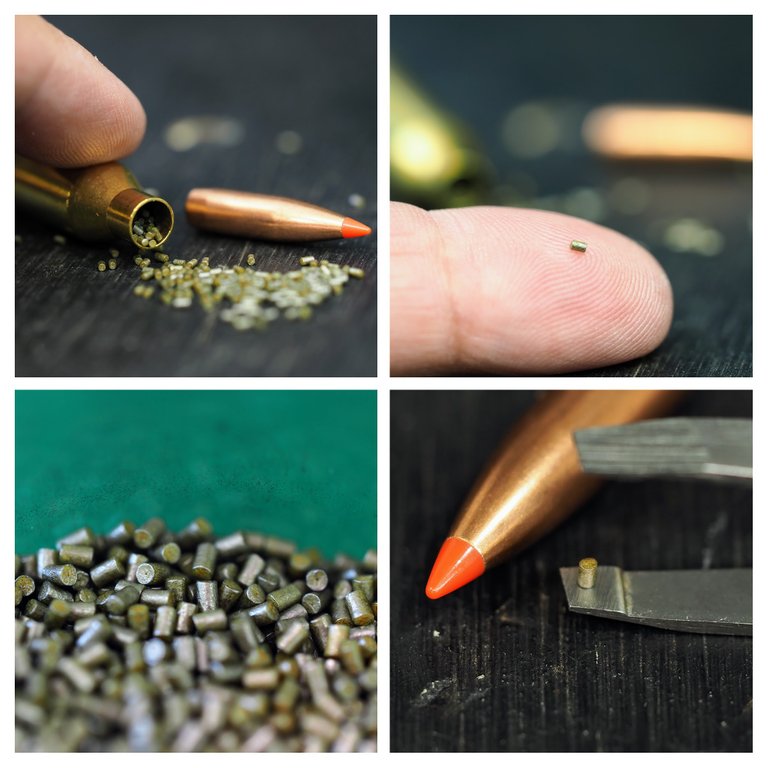

Below is an image of my beam scales. I simply set them at zero with the gold dish set upon the cradle by winding the other end of it up and down to level it off.

Once that's done I set the 40.9 grain-weight using little weights as you can see. Then I throw the measure of powder from the hopper into the gold dish (not literally throw it, that's just the term used) and then set the dish on the cradle. It's either perfect, (about 10% of the time) or I have to add or take pellets to make the weight perfectly precise. Thanks tweezers.

The powder is put into the brass case which has already undergone all the preparation work including having a new primer inserted and then is placed into the press and held there with the case holder. I take a projectile, place it into the neck and then work the handle of the press which pushes the case and projectile up into the seating die pressing the projectile into the case neck. When that is done, I have a finished round of ammunition.

There's no real trick to this process although because I work with very small tolerances and want precision, I ensure the overall length of each round is within a set tolerance that I determine during the load development process as mentioned earlier. The seating die in the press is set (by me) to push the projectile to a certain depth which then dictates the overall length (OAL) of the round.

Below you can see a completed round at lower left. You might be able to make out some shavings at the neck of the round (the top of the brass part) which is fine filings that have been sheared off the projectile by the seating process. To the lower right you can see some of those shavings laying on the case holder after I've made about a hundred rounds.

The image below top is to demonstrate how far the projectile actually gets pushed into the case and these minute filings do not affect the flight of the bullet.

I measure each round when it is complete to ensure it is within tolerance. I generally know they will be but I like to check and recheck and over the years have found one or two that have been either too long or short. Too long and they may not feed from the magazine into the chamber properly and being too short can affect accuracy. The throat-jump (distance from the projectile's ogive to the rifle's lands) can affect accuracy. Again, I have tested all of this for each of my long range rifles and developed a load/round specifically for each; some like a linger jump and some shorter.

The OAL for these rounds is 2.17 inches measured from the base of the case to the ogive of the projectile. This is done using a comparator gauge affixed to a vernier caliper. I work around a tolerance of 2.1695 to 2.1710 inches but most hit the 2.17 exactly. Shorter or longer than that tolerance and the round is considered substandard and pulled apart to be rebuilt to meet tolerance.

In the image below, you can see that the comparator gauge rests on the ogive and the OAL is taken from there. The reason for this is that the tip/nose of the bullet, the meplat, is not always exactly precise and the ogive is.

Once measured for length the last stage is giving the round a shake next to my ear; this is done to ensure the powder is in there, a sort of check-measure for the check I've already done and the check before that done through the reloading process. Shooting a round without powder will result in a projectile stuck in the barrel and that'll fuck up a shooters day for sure, and possibly cause injury or death.

I made a couple hundred of these to bring my stock of this calibre back to its minimum of several hundred. I rotate oldest to newest as I shoot and work my way through over the course of time. It was a relaxing time, coffee, music and the repetitive process of reloading often is, (when things are going right.) It takes concentration, it's not something one wants to mess up, but having single-focus on something gives the brain a little time take a rest from all the other stuff.

So that's it, a few very basic words about my reloading session. If you have any questions feel free to ask, I know a thing or two or feel free to make a comment if you'd like.

Design and create your ideal life, don't live it by default; tomorrow isn't promised so be humble and kind - galenkp

[All original and proudly AI free.]

Every image in this post is my own.

Olympus OM-D E-M10 Mark III was used to capture these images.