I get paid because I work. I get paid because the machines work. When the machines do not work, no money comes in and I do not get paid. All hail the machines.

I wrote that when I was in grade 4, living in China was definitely a different experience.

Not much has changed though, and it still rings true. When the machines do not do what they aught then there is a problem.

This week basically revolved around just shutting shit down. First, my new machine which was supposed to never ever require maintenance. I wrote about that sublimation / white toner printer here

Tomorrow I will be sending the whole printer and its toners back to them and hope they get it working as it should. So far they keep sending me the toner which has a problem only for the new one to also have the exact problem. Pretty much over a $1500 pain in the arse.

Then the biggy.

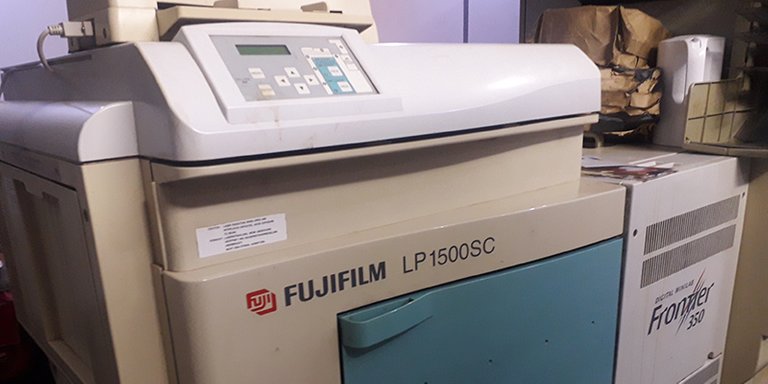

This is the main machine in the shop, an old school chemical photo lab. Way too many moving parts for anything to make sense and the software runs only on windows 7 if you fiddle with it.

So it is pretty old , about 20 years but when it runs it bloody runs. Which to be fair is mostly.

On-off the past couple of weeks, probably because it was chatting with the stupid laser printer. It decided to start jamming after every few prints.

Progressively I have been fixing issues as I go, and each of those then leads to another.

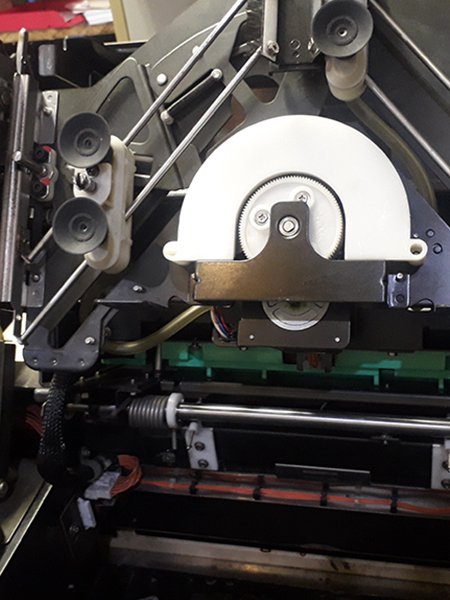

At first, I thought ok it is in the racks. Since the machine has 6 racks where the paper gets fed into starting with chemical, bleach then 4 water racks. As you can see in the picture they have a lot happening in them so it could be a gear or roller not running.

After a pretty big heap up, I guess my prayer was answered and a bottom gear on the chemical rack snapped in half. Phew that is a nice clear issue... Since nothing rolls , then nothing can feed.

Problem fixed.

A month ago we had a continual issue with the feeding rollers also. They are the ones that take the paper from the laser unit (not laser printer). The laser unit exposes the paper to light.

Then feeds it into the chemical rack and the process starts.

So a month ago I had my boss suck it up and send the technician which costs a fuckton, about $400 to come and fix that.

I call this the feeder unit or rollers. No clue what it really is but it cost $400 to repair.

So you see the red rubbers? They shrink wrapped that onto the rollers.

The error I have been getting that jams my machine is where the paper would just stop feeding into the chemical rack.

- This is also because the bottom of the racks gear snapped.

- It snapped because there are no sensors to say there is paper at the bottom.

- The paper stacks but in the water and chemicals you only see the top bits.

- Send enough prints through and that pressure overflows into the feeding unit.

- This caused the shrink-wrapped rubbers to detach from the shaft.

- Ka BOOM

Open Side of paper and laser unit top

Feeder / laser unit lifted up

Feeder rollers below the laser unit

Feeder rollers below the laser unitI know the pictures are bit confusing, but just know it is like a damn puzzle removing those rollers. In the right picture you will see there are black bands over the red rubbers. Usually a person can try move them back on with a long object while the machine runs to keep them from coming off and blocking the sensors.

Those bands blocking the sensors because they shift off of the rubbers was what the tech "fixed". Introducing, a new variable which is, the rubbers only use the bands as guides so not really required. The rubbers should though at all times be moving.

If they do not move the paper can get lagged, which causes the paper to not reach the next sensor in time and then the machine stalls.

Fortunately, we have a second never worked since the day we got it because it is a fixer-upper machine and its components fit the main moneymaker perfectly.

So after a week, actually more. On off fixing, cussing, detesting every single moment because things work then don't work. It was a relief to spend 8 hours after work on a Saturday getting help over the phone and installing the new unit myself. It is like one of those you can feel it in your bones things when I told the tech hey these rubbers are not moving.

So everything on that front seems fine, tomorrow it is sending the stupid laser printer in to get the maintenance it supposedly never requires.

In other news, maybe think a bit more about big purchases before spending your crypto. Because that shit can bite you in the ass and you will be recovering for quite some time.