I'd got a pile of wood and hundreds of screws checked and counted off present and correct. I'd got the new drill. I'd got a house that smelt like an explosion in a pesticide factory and I'd got a wife that was nagging me to an early grave. It was time to build the damned climbing frame!

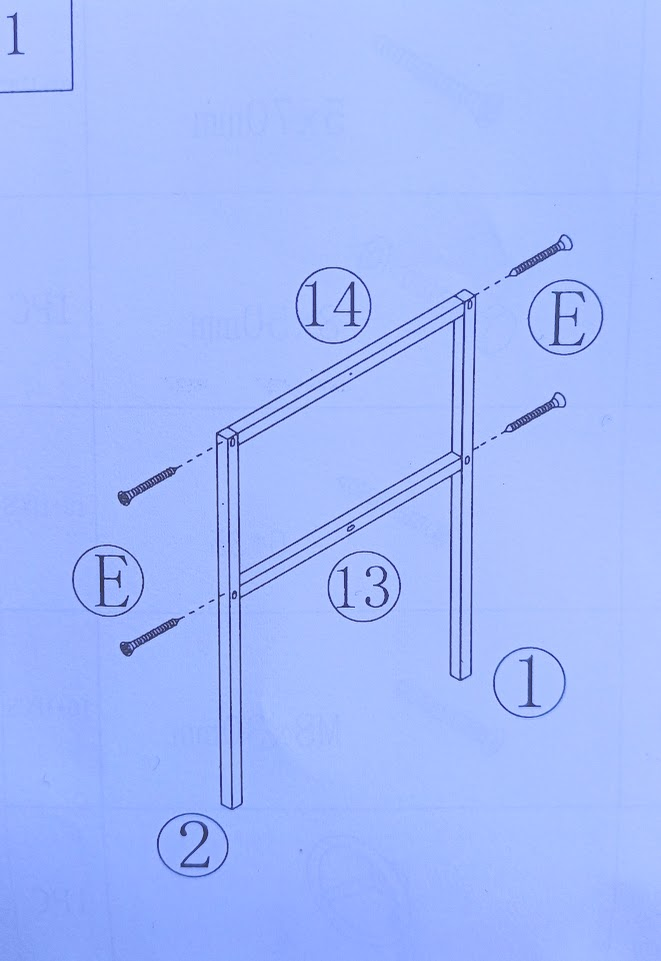

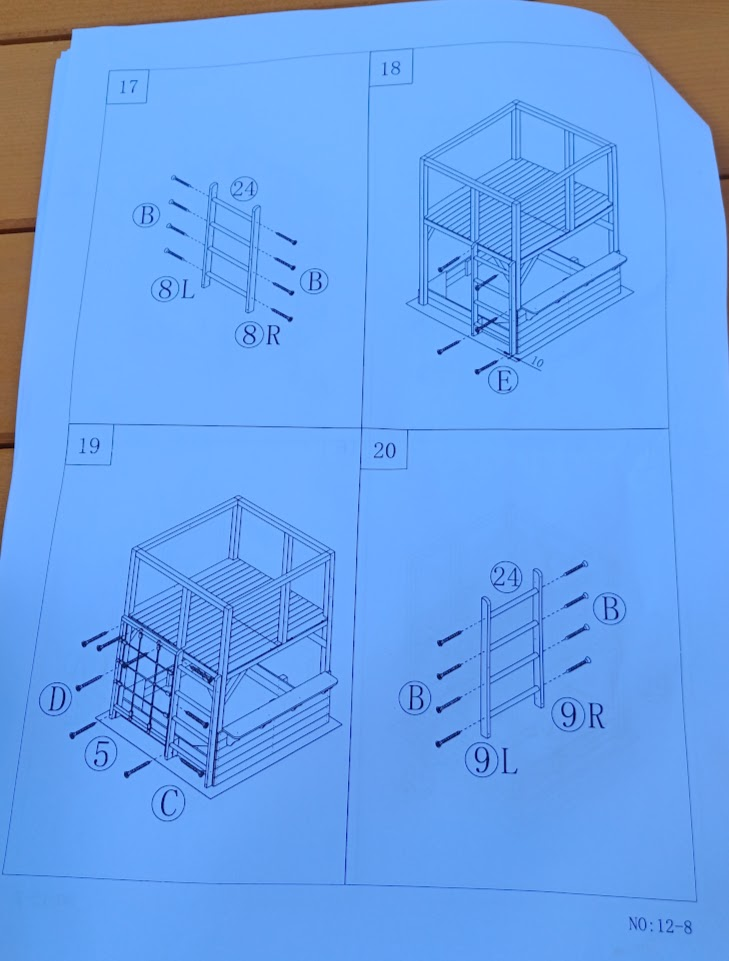

Now the first thing to point out that this wasn't one of those dreadful pieces of cheap 'furniture' the wife had ordered from China. The climbing frame was made by a Thai company, Gadeaux Kids and the packing and quality were excellent, as was the instruction book. Clear diagrams that were easy to follow and had the part numbers, orientations and screw sizes clearly marked.

The wood was obviously pine but as mentioned, had been treated, screw holes were pre-drilled and countersunk and the mortise and tenon joints were clean and precise. Even the factory ends were square and clean and the every piece of wood smooth as a baby's arse. No one was going to end up with splinters!

So, the only tools required were three screwdrivers (bits), phillips 2 and 3 and a wide flat blade, and a tape measure. I gave a lot of thought to whether I should glue the joints and decided against it because I worry that at some time I might need to replace a rotten piece of wood or the wife might need it taking apart and moving and in any case, there were a lot of screws, cross members and corners holding it all together.

The basic four sides went together very easily and in the absence of a set square or any clamps, decided to build the frames on the patio using the tiles to get everything squared up as much as possible. This wasn't that important as there was always going to be a little play but it would definitely help make life easier as I added flooring and corner reinforcements.

Keeping the frames pushed against the step below the patio doors also helped to keep everything straight as making this alone made things a little more difficult.

So with the main frames built, it was time to put them together. Easier said than done alone as they were awkward rather than heavy but by leaning one frame against the wall and creating two 'L' shapes which were self supporting, I managed to get the thing together, loosely screwed and self supporting until I was happy it was fairly square then tightened everything up.

If I were making this myself rather than from a kit, I would have used stouter timbers.

So next came two, ready made floor panels which fit really well as I'd managed to get the whole thing quite square.

According to the instructions, I should just leave them loose to keep the shape but not screw them in until later when other cross members and supports had been put in place.

![]

)

)Next job was to screw in some corner supports. Thankfully the holes were pre-drilled as drilling at an angle without a jig can be pretty tricky but again, this excellent kit had me covered and also at this point, the accuracy of the squareness again came into play as the pieces sat perfectly and just added some 'beefiness' to the structure.

The rest of the side parts, except the ladders which I had to put together, were pre-made panels and they slotted into place perfectly, as per the plans. A little bit of fencing and then the final two jobs were screwing in the steering wheel and the plastic rocks onto the climbing wall. I'm an old hand at that!

And that was it. . The timber had already been treated with a pesticide to try and keep the termites away but anything wooden is going to struggle with the heat and tropical monsoon so I thought it worthwhile to give it a light sanding and a couple of coats of thinned down lacquer, making sure I used decent paintbrushes as cheap ones lose their bristles very easily when painting on lacquer!

The proof of the pudding though is in the eating, and in this case, the kids absolutely love it! At close to £400, I'm not sure it's exactly a bargain but it certainly went together easily with clear instructions and nothing missing. Anyone could have built it although it would be better with two people. I did have two helpers, but they were there simply to shout instructions and rush me along...

. We are glad to see you using

. We are glad to see you using