When I was a boy, I had a very crafty cousin who wielded a large Bowie knife. To my amazement, he'd made the knife himself, fashioned from a lawn mower blade. I've always wanted to give such an endeavor a try. A couple of weeks ago I was jogging along and noticed an edger blade along the roadside. I picked up the metal...now was my chance.

The E5000 edger blade knife.

The E5000 edger blade knife.Below is the edger blade that I found. It seemed relatively new:

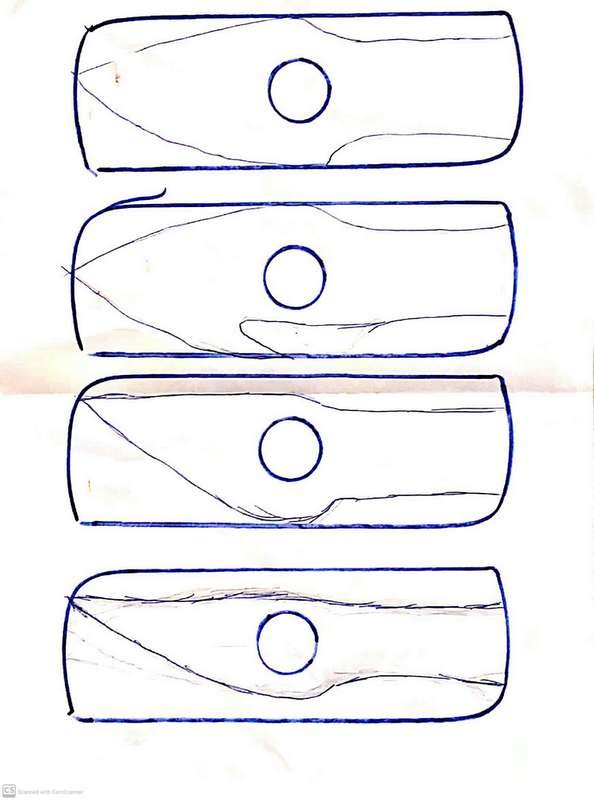

I had to think about a design or shape, so I Googled "edger blade knife" or something like that. Below are some images that popped up. They all looked very nice yet seemed a bit beyond my skill level. Still, they gave some ideas:

Time to trace the blade and draw out some rough ideas:

After consulting with my nephew, who has good sense about this kind of hunting/fishing/outdoorsy stuff, I decided to shoot for something between the top and bottom sketches. It was time to put the edger blade in the vise, to get out the angle grinder, and to make sparks fly.

After a bit of grinding, the blade was roughed out, as below.

For the handle, I had a piece of oak flooring laying around with a tongue-in-groove cut. I decided I'd simply deepen the tongue-in-groove and then set the blade inside, like below:

When I popped out the central part of the slot, the top half of one side broke off. No problem, that's what wood glue is for.

The cheap 5-minute epoxy has done me right for several projects and I've always been satisfied with it. So, the plan was to simply set the blade in the slot of the handle. Then, I'd pour in the epoxy to set the blade in place.

In retrospect, I should have taken more time and care to form my tape-mold more accurately and securely. I had epoxy leakage.

The next day, things were set up solidly.

The only thing left to do was to get back to the grinder and cut down the handle. After cutting steel, cutting through wood and epoxy was easy. As a side note, the burning smell of the epoxy smelled oddly like roast duckling...not sure what that means.

There was only one thing left to do...name the knife. I initially thought I'd call it the Edge 5000 since it came from an Edger blade. Then, I figured I'd shorten it down to the E5000.

The E is for Edge(r), but also as a tip-o'-the-cap to my nephew.

The 5000 is because that's cool.

A little wood burning on the handle, some filing and sharpening with a hand file, and the E5000 is done.

Everything I make is ugly, but it's strong. The handle is bigger than I'd imagined at first, but it feels very solid in my hand. The E5000 definitely fits with my construction trend. If I had to choose between ugly and strong, or pretty and weak, I'll go with the former. Overall, for a first try, I'm pleased.

Next time, for the E6000...

Some final thoughts looking back and looking forward:

- The blade is going to rust. You can see some oxidation in the photos even during the construction period. This has everything to do with the type of steel (it's not stainless steel) and is probably unavoidable for an edger-blade knife. I put a thin coating of oil on it when I finished, which should help, but beyond that the rusting is probably unavoidable. (Any tips? I could use them. Leave them as a comment.)

- Next time, I'll take more time and care when putting on the handle. I'll likely make it smaller and more of a finished handle to start, and create a better mold, when gluing it. It took all of the epoxy for this one; I likely can be more efficient.

- Perhaps I'll try a different design as well, just for the fun of it.

- I'll be on the lookout for more blades laying around, and especially for a lawn mower blade! The LM5000?

Not on Hive? The top benefits of Hive: (1) no ONE person/group runs it, (2) YOU own your content, and (3) YOU earn the rewards your that content generates. Learn more or consider using my referral link to get your free account here.

:)