Every spring, neighbors of ours purchase half a dozen weaner pigs to raise, butcher, and sell for meat. Last summer we were able to purchase half a pork from them, including a large bundle of pork fat. I learned how to render lard in 2013, but had not done it since then, and was reluctant to launch into that project. So the fat languished in my freezer until this week, when I plopped it into my old green cooler and took it along to my sister's house. She has rendered lard many times, and was more than happy to help with the job, knowing she would get half the lard in the end.

Normally when I make that drive to Montana I stop and take plenty of touristy pictures to share on Hive . But this time I went earlier in the year than usual, and it was very chilly, and it rained all the way. My rest stops featured hasty walks into visitors' centers to find a restroom. I stopped just once specifically to take exactly one picture:

But now I will make up for the lack of scenic pictures by posting plenty of lard-rendering photos!

My sister recently invested in a grinder attachment for her Kitchen Aid Mixer, and that is now on my wish list. What a wonderful, time-saving and energy-saving contraption!

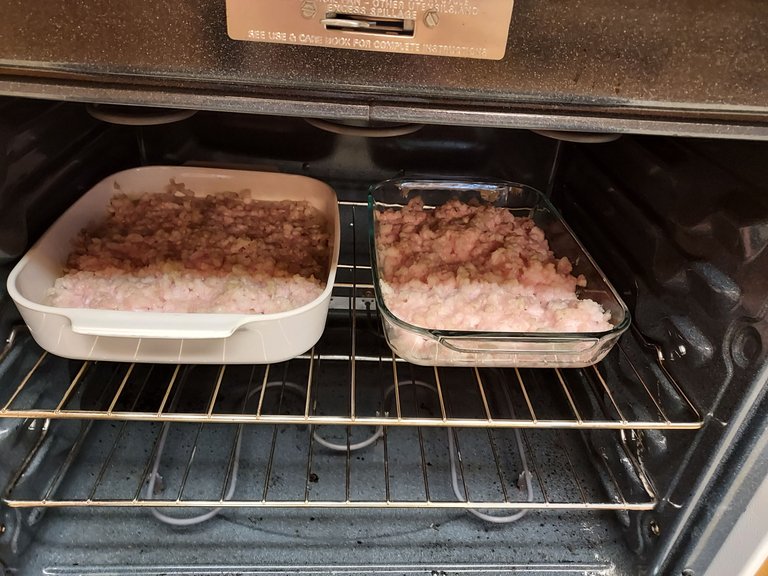

In a very short time, we had filled two large casserole dishes with ground fat, in addition to the crockpot seen in the first photo. The crockpot was turned to low, and the oven was set to 225. Ummm, that is to say, it was supposed to be set to 225. But I either didn't hear what my sister said, or just wasn't paying attention to what I was doing, and set it to 325. A couple of hours later, she could smell the pork cooking and looked into the oven to see how it was progressing.

Oops. The pork fat was supposed to melt, not cook! But the result was simply slightly-browner liquid lard, which we ladled into bowls. We filled a few jars with the darker lard, and will use it for savory cooking rather than pastries.

The remaining slightly-browned ground fat went back into the oven to render out more liquid, this time at the correct temperature.

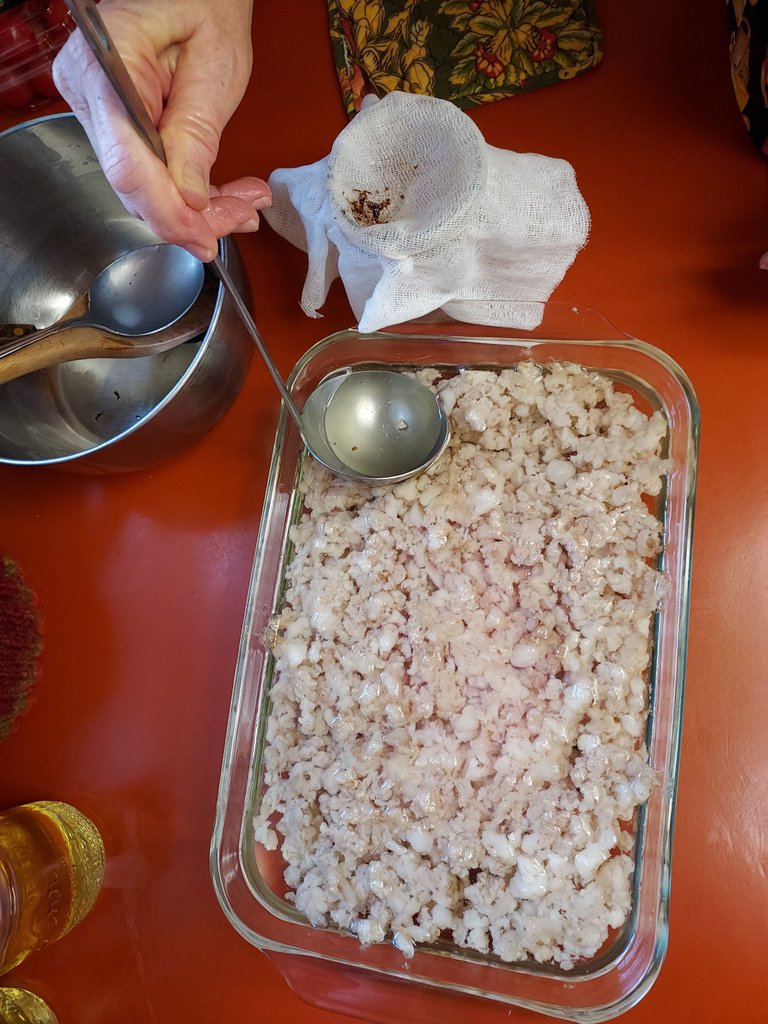

My sister began ladling the liquid lard into pint jars, using cheesecloth (held in place with a rubber band) to catch any remaining bits of solid fat or cracklings.

In addition to the three previously-mentioned containers of ground pork fat, we filled another 9x13 casserole dish and her largest kettle with ground pork fat. Those had to wait for their turn in the oven. We put the glass pan into my green cooler and set it outside the back door, and set the kettle on the woodpile beside the front door, since the great outdoors provided a perfect refrigerator for the day.

That next pan of ground pork fat was heated at the proper temperature, and did not get brown. The liquid lard was much clearer as well.

You can see the difference between the overheated lard on the right and the correctly heated lard on the left.

By late afternoon we had an assortment of jars with solidified lard and liquid lard in lighter and darker shades. We finished the job the next day, and ended up with about 22 pints of lard, plus plenty of pork cracklings to nibble on or use in recipes.

Now that I have worked with my sister on this project, and have refreshed my memory on how to do it, I hope to be able to do the entire job myself the next time, if necessary. But it's much more fun to work with my sister.