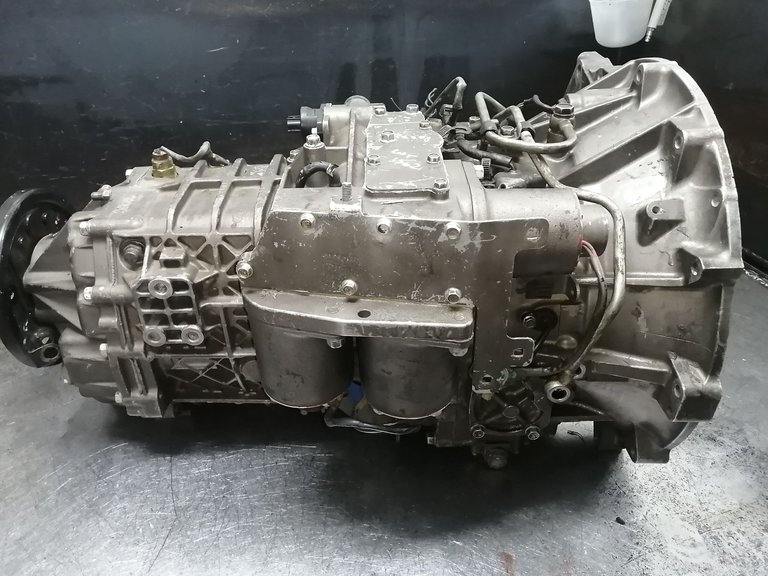

Jumping back to those big trusty transmissions. Well most of them at-least.

This specific one well it's a rebuilt transmission bought by the client and it doesn't want to shift to 6th gear, so it's already a rebuilt transmission so we will have to look for problems it wont be easily found and well it can be easily missed too.

I have to say I am quite excited on this one. It's a automatic transmission but it's more a hydraulically shifted manual transmission. With most of the things being gears and shafts it's only the front bell-housing piece that's actually somewhat automatic.

Now lets start tearing her up, slow and steady should get us there, it doesn't look like a completely crazy design and well it turned out to be a built that went like a dream, with that said we didn't do any stripping of the cluster shaft. merely looked for and found the fault, we actually did more work than what was really needed.

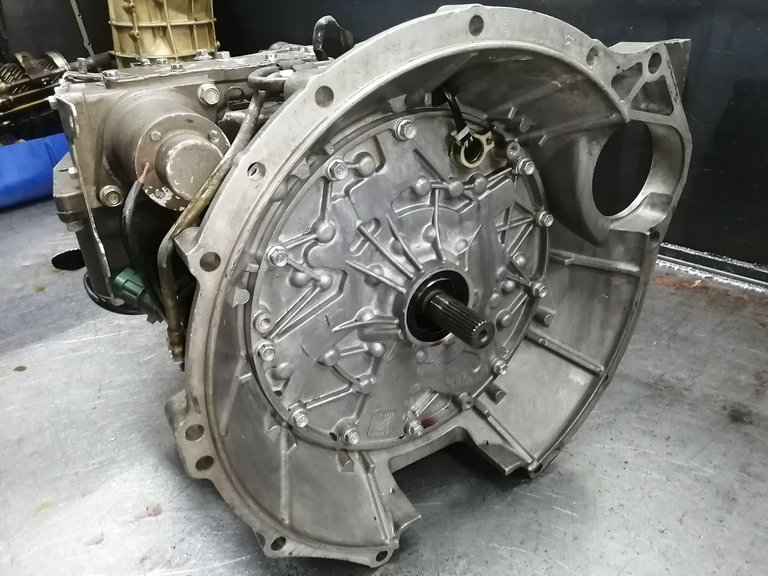

See it's got the Input shaft for the torque converter, I wasn't making it up 😅 it's really an automatic!

Well it's simple, let's start there where the bushes are the thickest. I have no fancy in keeping too much on the transmission when tearing it down, most of the time I tend to take out more than I need to, but then again this help tremendously when trying to clean everything.

Besides would it really kill you to remove most of the "not needed" to remove? perhaps like four bolts more or eight or ten? What, that adds to like 5 minutes?

So just do the damn effort, that's why most people never really advance in this field.. Be better among the thousands who try. Always!

Well of with whatever this may be called, yeah I'm new to this, but at-least I know I'll be able to figure out how it may work. But I don't think the problem lies there. That would be last resort as is can be removed after the transmission is re-fitted back to the vehicle.

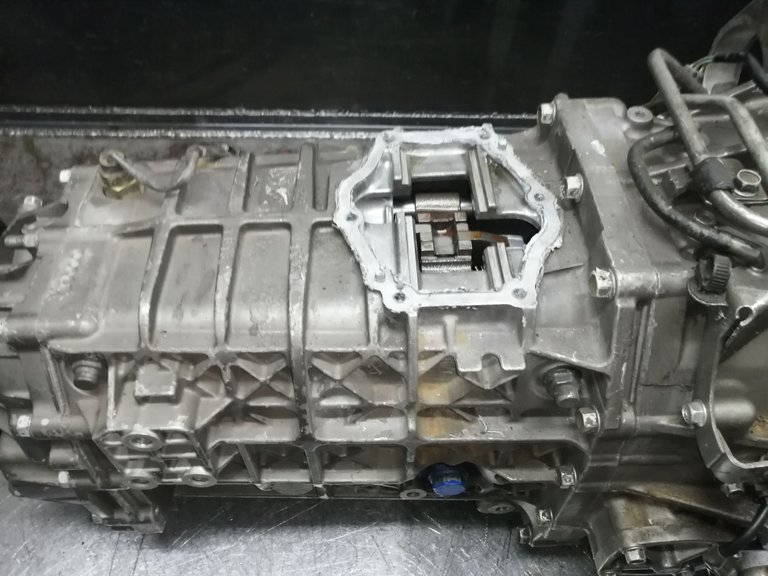

Oh yeah, we're doing a teardown again! I do enough but not alot!

I have to say it looks alot smaller now, I can actually see the originating manual transmission underneath that bulky hydraulic selector business really does give it a automatic look!

Looks quite ugly now won't you say?

It has finally begun, after moving to the rear I decided to start with the tail piece, naturally ofcourse, what I mean is I didn't remove all the bolts of the casing for the middle section just yet, I want to take it slow with new things laughs with most of the transmissions I just pull them apart and junk them in a box.

Don't get me wrong at the end of the day it's still one big puzzle but it's tricky to remember all the tricks each transmission hides, especially so if you do in-fact work on a wide range of them.

At-least the oil looks pretty neat, not alot of shavings or any of those bad signs showing up.

These jobs can go pretty high especially when the oil is filled with metal shavings, that stuff goes everywhere in between everything that creates friction, those shavings in turn cause uneven spots and then the wear starts happening.

AAAhhh hah! The concept is all too familiar this somewhat reminds me of a small Renault transmission, I've shared a bunch of teardowns on them, although this one is bigger so much bigger and alot different I have to say, yet the same...

With an odly weird selector stick thingy there.

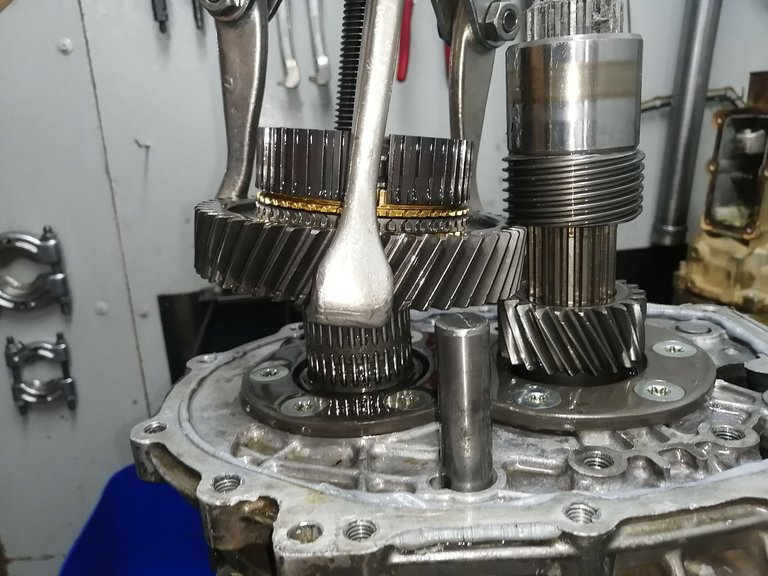

As always most of these have to be pulled of, the hub is interference with the shaft, not alot though, no need for a press or anything, it can also be simply and easily hammered back into place. If you work careful.

And here I thought I would need to benchpress the shit out of these gears to get them off. Turned out to be alot easier than any transmission I've ever dealt with!

All that's left is ti remove the center casing which houses the cluster shaft aswell as the counter shaft. By the looks of it it should pop right of with the help of tyre levers no problem!

I will need help though casings can sometimes be heavy and well I don't want this one slipping and bouncing off the table to burst now do I.

Ohhh I didn't expect this at all... I legitly thought it would be one ganky mess even though I did see the clean oil, the grime tends to stick to the metal. However this is for sure a rebuilt transmission, a very nice rebuild at that too, but with one little flaw that the builder thought would never happen ... Atleast not to him, now I wonder was it ignorance or spite? it does look somewhat purposefull.

I say that because there is no possible way to get that bent by normal use of the gear box. Hell even hard use wont really cause that, I can't think it will.

I know it's not easy to see but right where the little piece that is machined out it has a little bend. Now most might say okay this is something that can happen but no, in my opinion I think it was intentionally hammered and hammered hard for that matter. There are also hit marks on the opposite side of that indicating it was hit with something atleast. Something that has some sort of point.

It doesn't really matter now, aslong as we were able to identify the fault.

Of-course since we see no damage in any other place I'd take a safe bet and say that she can be refitted back into the truck after a slap together.

Notice the marks on the shaft, that is not suppose to be there, and the do look weird in some way, it doesn't look like the normal wear marks which are usually very straight lines. These are far from straight. Besides that it's suppose to be oiled everywhere so this wont happen. The other shafts show no signs of wear at all, why this one?

Connecting the people of #HIVE across South Africa. #hive