With the insulation and electrical installed, its time to cover up everything. The ceiling is done but the sides all need to be covered. We used metal roof paneling that are eight feet tall to cover up the bottom half of the wall. Then we will cover the top half using ladders. But for now we want to get the first level of paneling up. They will overlap by around two feet once both the upper and lower panels are installed.

In a month or so I should have my solar array complete, so this paneling will let us mount electrical panels and other things. The insulation is flammable so we do not want it exposed, the paper on it can ignite so it needs to be protected. That is why we are putting up panels as well. For the looks, protection, insulation properties and it just helps complete the core of the workshop.

My foreman lays the panels up and screws them into 2x4s that we mounted to the walls of the workshop. We place them every few feet so we can screw the panels in and secure them well to the wall.

We pop out the electrical outlets so we can plug in tools. That seems to take the most time, getting the cuts right and the outlets put through the metal sheeting.

Even though the workshop is not powered yet, all of the wires have been run and its ready for when my friends return to help me finish up the solar side of all of this.

Starting on the walls without any of the heated water lines, we work our way over to the more infrastructure filled areas.

Lots of wall to still do, but we are well on the way.

Rounding the corners we wrap one panel in the corner to cover missing panels. Seems to be the best way to handle this issue, otherwise we are cutting little pieces to fit in the corners.

I think the gray panels will look nice, they wont show getting dirty much but still light enough to help bounce more illumination in the room.

We got up to one of the walls where we have some rubberized plywood curing. This is used for the partitions for the chicken and duck home. This stuff will be dry in another week, then we can move it and complete this side of the wall. No worries we can start on the other sides in the mean time.

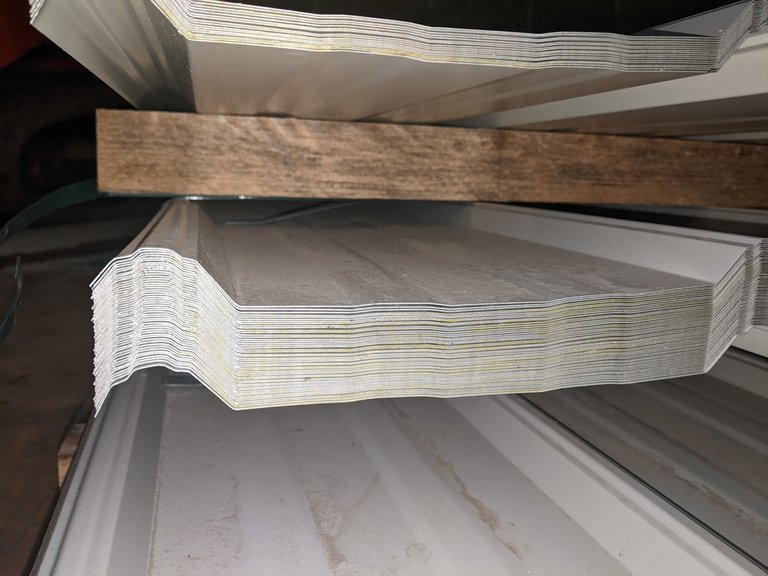

It is amazing how tightly stacked these panels are. It looks like it weighs next to nothing when you pull out three panels but the weight is indeed all there.

Whatever we do not use for the workshop we will save for another project. These are some good panels to have. My barns roof is looking a little worn so it may be worth replacing with these extra panels.

I think we will go through at least half if not three quarters of all of them.

We can move the rest of the panels using the skid steer and the fork attachment.